1985 OMC 65, 100 and 155 HP Models Commercial Service Manual, PN 507450-D, Page 277Get this manual

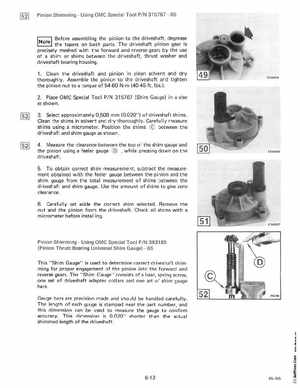

Pinion ShimmingUsing OMC Special Tool PIN 31576765

Before assembling the pinion to the driveshaft, degrease the tapers on both partsThe driveshaft pinion gear is precisely meshed with the forward and reverse gears by the use of shim or shims between the driveshaft, thrust washer and driveshaft bearing housing1Clean the driveshaft and pinion in clean solvent and dry thoroughlyAssemble the pinion to the driveshaft and tighten the pinion nut to torque of 54-60 Nm (40-45 ftIbs2Place OMC Special Tool PIN 315767 (Shim Gauge) in vise as shown3Select approximately 0,508 mm (0.020") of driveshaft shimsClean the shims in solvent and dry thoroughlyCarefully measure shims using micrometerPosition the shims between the driveshaft and shim gauge as shown4Measure the clearance between the top of the shim gauge and the pinion using feeler gaugewhile pressing down on the driveshaft5To obtain correct shim measurement, subtract the measurement obtained with the feeler gauge between the pinion and the shim gauge from the total measurement of shims between the driveshaft and shim gaugeUse the amount of shims to give zero clearance6Carefully set aside the correct shim selectedRemove the nut and the pinion from the driveshaftCheck all shims with micrometer before installingCOA3534