1985 OMC 65, 100 and 155 HP Models Commercial Service Manual, PN 507450-D, Page 203Get this manual

COB1314

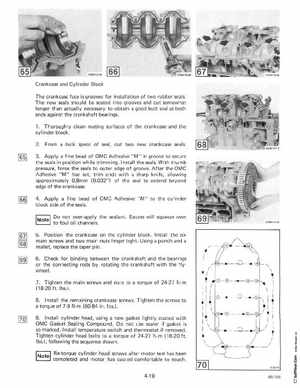

Crankcase and Cylinder Block The crankcase face is grooved for installation of two rubber sealsThe new seals should be seated into grooves and cut somewhat longer than actually necessary to obtain good butt seal at both ends against the crankshaft bearings1Thoroughly clean mating surfaces of the crankcase and the cylinder block2From bulk spool of seal, cut two new crankcase seals

3Apply fine bead of OMC Adhesive "M" in groove to secure the seals in position while trimmingInstall the sealsWith thumb pressure, force the seals to outer edge of grooveAfter the OMC Adhesive "M" has set, trim ends with sharp knife, allowing approximately 0,8mm (0.032") of the seal to extend beyond edge of the crankcase4Apply fine bead of OMC Adhesive "M" to the cylinder block side of the sealsDo not over-apply the sealantExcess will squeeze over to foul oil channels5Position the crankcase on the cylinder blockInstall the six main screws and two main nuts finger tightUsing punch and mallet, replace the taper pin6Check for binding between the crankshaft and the bearings or the connecting rods by rotating the crankshaft with the flywheel7Tighten the main screws and nuts to torque of 24-27 Nm (18-20 ftIbs8Install the remaining crankcase screwsTighten the screws to torque of 7-9 Nm (60-84 inIbs9Install cylinder head, using new gasket lightly coated with OMC Gasket Sealing CompoundDo not use sealer if gasket is so markedInstall temperature switch and thermostat if removedTighten cylinder head bolts to torque of 24-27 Nm (18-20 ftIbs, following the sequence shown-