1985 OMC 65, 100 and 155 HP Models Commercial Service Manual, PN 507450-D, Page 129Get this manual

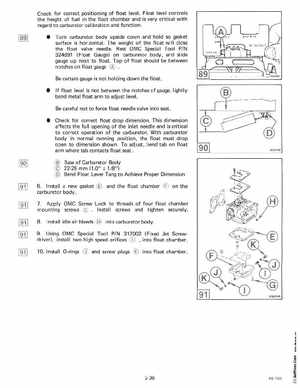

Check for correct positioning of float levelFloat level controls the height of fuel in the float chamber and is very critical with regard to carburetor calibration and fu nction Turn carburetor body upside down and hold so gasket surface is horizontalThe weight of the float will close the float valve needleRest OMC Special Tool PIN 324891 (F loat Gauge) on carburetor body, and sl ide gauge up next to float Top of float should be between notches on float gauge Be certain gauge is not holding down the float If float level is not between the notches of gauge, lightly bend metal float arm to adjust levelBe careful not to force float needle valve into seat Check for correct float drop dimensionThis dimension affects the full opening of the inlet needle and is critical to correct operation of the carburetorWith carburetor body in normal running position, the float must drop open to dimension shownTo adjust, bend tab on float arm where tab contacts float seat 90