1985 OMC 65, 100 and 155 HP Models Commercial Service Manual, PN 507450-D, Page 111Get this manual

Float Valve and Needle ValveAll Models

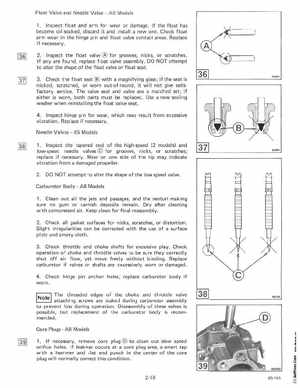

1Inspect float and arm for wear or damageIf the float has become oil-soaked, discard it and install new oneCheck float arm wear in the hinge pin and float valve contact areasReplace if necessaryInspect the float valve for grooves, nicks, or scratchesIf any are found, replace float valve assemblyDO NOT attempt to alter the shape of the float valve or float seat =

3Check the float seat with magnifying glass; if the seat is

nicked, scratched, or worn out-of-round, it will not give satisfactory serviceThe valve seat and valve are matched set; if either is worn, both parts must be replacedUse new sealing washer when reinstalling the float valve seat

4Inspect hinge pin for wear, which may result from excessive vibrationReplace if necessaryNeedle Valves65 Models Inspect the tapered end of the high-speed (2 models) and low-speed needle valves for grooves, nicks, or scratches; replace if necessaryWear on one side of the tip may indicate vibration from damaged propeller1

DO NOT attempt to alter the shape of the low speed valve