1980 Johnson 4HP Service Manual, Page 24Get this manual

CLEANING, INSPECTION AND REPAIR GENERAL INSTRUCTIONS Clean all parts, except cork float, in solvent and bIow dry00 NOT dry parts with cloth as lint cause troubIe in the reassembIed buretorsure all particles of gaskets moved from gasket surfacesFlush out passages in the carburetor body and float chamber gummy deposits with solvent and remove with Engine CleanerCertain solvents will not remove this gum which accumulates the particularly in the float chamber and needle valves

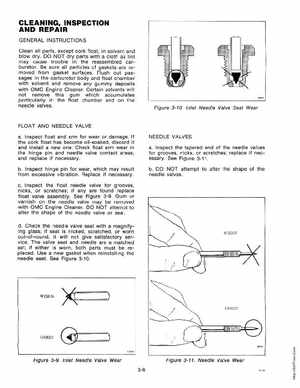

Figure 3-10Inlet Needle Valve Seat Wear

FLOAT ANO NEEOLE VALVE Inspect float and for wear damageIf the cork float has oil-soaked, discard it new Check float wear in and install the hinge pin and needle valve contact areas, and replace if necessaryInspect hinge pin for wear, which result from excessive vibrationReplace if necessaryInspect the float needle valve for grooves, scratches; if found replace nicks, float valve assembIySee Figure 3-9Gum varnish the needle valve removed Engine Cleaner00 NOT attempt to with alter the shape of the needle valve sealdCheck the needle valve seat with magnifying glass; if seat is nicked, scratched, worn out-of-round, it will not give satisfactory sermatched viceThe valve seat and needle set; if either is worn, both parts must placedUse new gasket when reinstalling the needle seatSee Figure 3-10NEEOLE VALVES nspect the tapered end of the needle valves for grooves, nicks, scratches; replace if essarySee Figure 3-11 00 NOT attempt to alter the shape of the needle valves