1978 Johnson 55 HP Outboards Service Manual, Page 66Get this manual

CLEANING, INSPECTION AND REPAIR CYLINDER BLOCK AND CRANKCASE Check cylinder walls for excessive wear and check cylinder ports for carbon accumulationCylinder walls wear in various degrees, depending on lubrication and conditions under which the motor is operatedMajor portion of wear is in the port area and the area covered by ring travelCheck cylinder for size and wall straightness by using an inside micrometerRefer to Section for specified dimensionsReplace cylinder block, or rebore block for oversize pistons if wear is in excess of .003" (0.08 mm)Pistons and ring sets are available .030" oversize

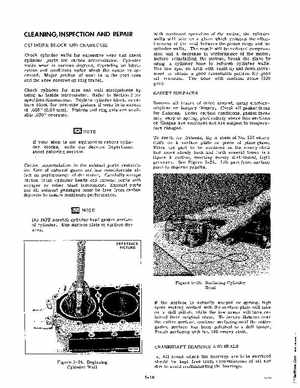

With continued operation of the motor, the cylinder walls will take on glaze which reduces the effectiveness of the seal between the piston rings and the cylinder wallsThe result will be reduced compression and decrease in performance of the motorBefore reinstalling the pistons, break the glaze by using cylinder hone to refinish cylinder wallsUse low rpm on drill with rapid up and down movement to obtain good crosshatch pattern for good oil retentionUse hone with medium stone (220 grit) GASKET SURFACES Remove all traces of dried cement, using trichlorethylene or lacquer thinnerCheck all gasket faces for flatnessUnder certain conditions, gasket faces may warp or spring, particularly where thin sections or flanges are employed and are subject to temperature changesTo check for flatness, lay sheet of No120 emery cloth on surface plate or piece of plate glassPlace the part to be surfaced on the emery cloth and move slowly back and forth several times in figure motion, exerting evenly distributed, light pressureSee Figure 5-25Lift part from surface plate to observe results