1978 Johnson 4HP outboards Service Manual, Page 23Get this manual

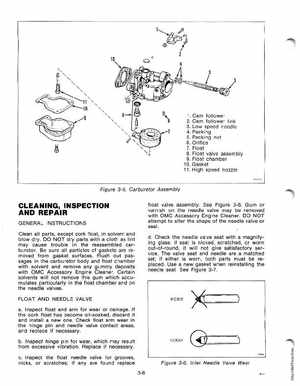

1, I'1Cam follower 2Cam follower link 3Low speed needle 4Packing 5Packing nut 6Orifice 7Float 8Float valve assembly 9Float chamber 10Gasket 11High speed nozzle

Figure 3-5Carburetor Assembly

CLEANING, INSPECTION AND REPAIR

GENERAL INSTRUCTIONS Clean all parts, except cork float, in solvent and blow dryDO NOT dry parts with cloth as lint may cause trouble in the reassembled carburetorBe sure all particles of gaskets are removed from gasket surfacesFlush out passages in the carburetor body and float chamber with solvent and remove any gummy deposits with OMC Accessory Engine CleanerCertain solvents will not remove this gum which accumulates particularly in the float chamber and on the needle valvesFLOAT AND NEEDLE VALVE aInspect float and arm for wear or damageIf the cork float has become oil-soaked, discard it and install new oneCheck float arm wear in the hinge pin and needle valve contact areas, and replace if necessarybInspect hinge pin for wear, which may result from excessive vibrationReplace if necessarycInspect the float needle valve for grooves, nicks, or scratches; if any are found replace 3-6