1978 Johnson 175, 200, 235 HP Outboard Service Manual, Page 177Get this manual

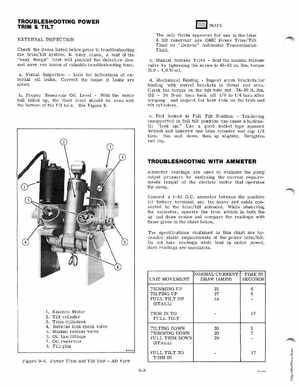

TROUBLESHOOTING POWER TRIMTILT EXTERNAL INSPECTION Check the items listed below prior to troubleshooting the trimtilt systemill many cases, test of the "easy things" first will pinpoint the defective item and save you hours of valuable troubleshooting timeaVisual InspectionLook for indications of external oil leaksCorrect the cause if leaks are notedbProper Reservoir Oil LevelWith the motor full tilted up, the fluid level should be even with the bottom of the fill holeSee Figure 9The only fluids approved for use in the trimtilt reservoir are OMC Power TrimTilt Fluid or "Dexron" Automatic Transmission FluidcManual Release ValveSeat the manual release valve by tightening the screw to 45- 55 inlbstorque (5.06.0 Nm)dMechanical BindingInspect stern brackets for binding with swivel brackets in thrust rod areaCheck the torque on the tilt tube nut 24- 26 ftlbs(3236 Nm) then back off 18 to 14 turn after torquing and inspect for bent rods on the trim and tilt cylinderseUnit locked in Full Tilt PositionTrailering unsupported in full tilt position can cause hydraulic "lock up Use good socket type spanner wrench and unscrew one trim cylinder end cap 14 turnRun unit down, then up slightlyRetighten end cap