1978 Johnson 175, 200, 235 HP Outboard Service Manual, Page 62Get this manual

tapered surfaces with solvent and blow dry with compressed airInspect both tapers for burrs and ni cks Replace flywheel and nut but do not torqueCheck for spark using spark testers with gap set to 716" (11 mm)See Figure 4-31AIf spark jumps gap, tighten nut to torque specified in Section 2Timing adjustment is made with timing lightSee Figure 4-8If timing is not correct, readjustment of the fully advance stop screw is requiredSee Figure 4-7 SPARK PLUGS

Inspect plugs for cracked porcelain and excessively worn electrodesIf electrodes are worn, plug should be replacedSee speCifications for correct replacement of spark plugPoor motor performance and premature spark plug failure may result from improper spark plug installationBefore installing the plug, be sure the plug seat in the cylinder head is clean and free from obstructionsScrew the plug in by hand, then tighten to the specified 17-12 to 20-12 foot-pounds (24-27 N.m)

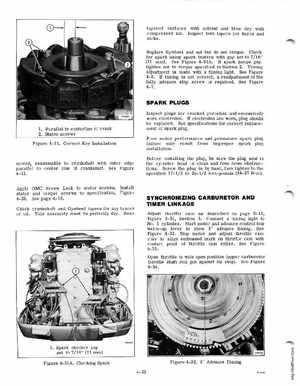

1Parallel to centerline of crank 2Stator screws Figure 4-31Correct Key Installation