1978 Johnson 175, 200, 235 HP Outboard Service Manual, Page 29Get this manual

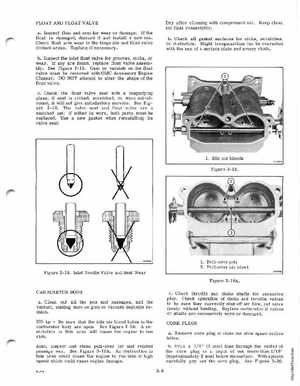

FLOAT AND FLOAT VALVE aInspect float and arm for wear or damageIf the float is damaged, discard it and install new oneCheck float arm wear in the hinge pin and float valve contact areasReplace if necessarybInspect the inlet float valve for grooves, nicks, or wearIf any are found, replace float valve assemblySee Figure 3-18Gum or varnish on the float valve must be removed with OMC Accessory Engine CleanerDO NOT attempt to alter the shape of the float valvecCheck the float valve seat with magnifying glass; if seat is nicked, scratched, or worn out-ofround, it will not give satisfactory serviceSee Figure 3-18The valve seat and float valve are matched set; if either is worn, both parts must be replacedUse new gasket when reinstalling the valve seat Dry after cleaning with compressed airfor final reassembly

Keep clean

bCheck all gasket surfaces for nicks, scratches, or distortionSlight irregularities can be corrected with the use of surface plate and emery cloth

1Idle air bleeds Figure 3-19