1976 Johnson 2HP 2R76 Outboard Motor Service Manual, Page 41Get this manual

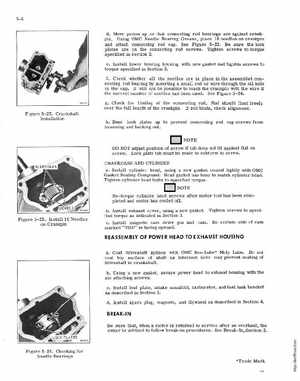

5-8 dMove piston up so that connecting rod bearings are against crankpinUsing OMC Needle Bearing Grease, place 16 needles on crankpin and attach connecting rod capSee Figure 5-23Be sure the lock plates are on the connecting rod screwsTighten screws to torque specified in Section 2eInstall lower bearing housing with new gasket and tighten screws to torque specified in Section 2fCheck whether all the needles are in place in the assembled connecting rod bearing by inserting small rod or wire through the oil hole in the capIt will not be possible to touch the crankpin with the wire if the correct number of needles has been usedSee Figure 5-2492 0

gCheck for binding of the connecting rodRod should float freely over the full length of the crankpinIf rod binds, check alignmenthBend lock plates up to prevent connecting rod cap screws from loosening and backing outNOTE DO NOT adjust position of screw if tab does not fit against flat on screwLock plate tab must be made to cOluorm to screwCRANKCASE AND CYLINDER aInstall cylinder head, using new gasket coated lightly with OMC Gasket Sealing CompoundHead gasket has boss to match cylinder headTighten cylinder head bolts to specified torque