1976 Johnson 2HP 2R76 Outboard Motor Service Manual, Page 33Get this manual

4-8 ILLUSTRATION TYPICAL OF THRU 40 HP

dCheck crankshaft and flywheel tapers for any traces of oilThis assembly must be perfectly dryswab tapered surfaces with solvent and blow dry with compressed airInspect both tapers for burrs or nicksNOTE DO NOT permit solvent used to clean tapers to wash oil out of oiler wick

ARMATURE PLATE

Figure 4-19Checking Timing with Engine Running

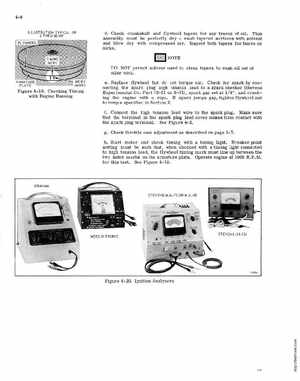

eReplace flywheel but do not torque nutCheck for spark by connecting the spark plug high tension lead to spark checker (Stevens Experimental CoPart #S-21 or S-31), spark gap set at 14", and cranking the engine with ropeIf spark jumps gap, tighten flywheel nut to torque specified in Section 2fConnect the high tension lead wire to the spark plugMake sure that the terminal in the spark plug lead cover makes firm contact with the spark plug terminalSee Figure 4-2gCheck throttle cam adjustment as described on page 3-7hStart motor and check timing with timing lightBreaker point setting must be such thatwhen checked with timing light connected to high tension lead, the flywheel timing mark must line up between the two index marks on the armature plateOperate engine at 1000 R.P.Mfor this testSee Figure 4-19