1976 Evinrude 200 HP Outboards Service Manual, PN 5199, Page 121Get this manual

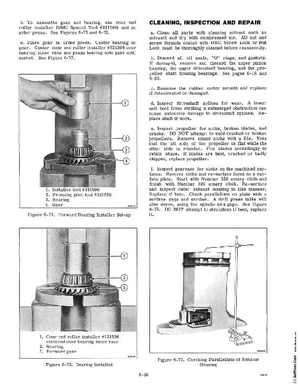

dTo assemble gear and bearing, use cone and roller installer (OMC Special Tool #321596) and an arbor pressSee Figures 6-71 and 6-72ePlace gear in arbor pressCenter bearing on gearCenter cone and roller installer #321596 over bearing inner race and press bearing onto gear until seatedSee Figure 6-72 CLEANING, INSPECTION AND REPAIR

aClean all parts with cleaning solvent such as solvasol and dry with compressed airAll nut and screw threads coated with OMC Screw Lock or Nut Lock must be thoroughly cleaned before reassemblybDiscard all oil seals, "0" rings, and gaskets If damaged, remove and discard the upper pinion

bearing, the upper driveshaft bearing, and the propeller shaft housing bearingsSee pages 6-16 and 6-23cExamine the rubber motor mounts and replace

if deteriorated or damaged

dInspect driveshaft splines for wearA lower unit bent from striking submerged obstruction can cause extensive damage to driveshaft splinesReplace shaft if worneInspect propeller for nicks, broken blades, and cracksDO NOT attempt to weld cracked or broken propellersRemove minor nicks with fileNote that the aft side of the propeller is flat while the other side is roundedFile blades accordingly to retain shapeIf blades are bent, cracked or badly chipped, replace propellerfInspect gear case for nicks on the machined surfacesRemove nicks and re-surface faces on surface plateStart with Number 120 emery cloth and finish with Number 180 emery clothRe-surface and inspect outer exhaust housing in like manner Replace if bentCheck parallelism on plate with surface gage and scriberA drill press table will also serve, using the spindle as gageSee Figure 6-73DO NOT attempt to straighten if bent, replace