1974 Johnson 40 HP Outboard Motors Service manual, Page 78Get this manual

fIf the pinion doe!:! not properly engage the flywheel, the pinion and screw shaft assembly may be worn, distorted, or dirtyLocate cause of binding and correct before completing assembly gThe starter solenoid is sealed unit and is serviced only as an assemblyTo test the solenoid, disconnect leads to solenoid terminalsConnect an ohmmeter set to low ohm scale between terminals and BConnect 12 volt supply between terminals and DSee Figure 7-12Solenoid plunger should give an audible click and ohmmeter should read zero ohms

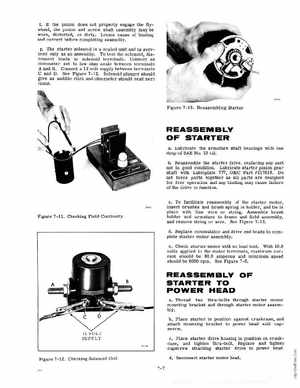

Figure 7-13Reassembling Starter

REASSEMBLY OF STARTER

aLubricate the armature shaft bearings with one drop of SAE No10 oilbReassemble the starter drive, replacing any part not in good conditionLubricate starler pinion gear shaft with Lubrtplate 777, OMC Part 1 317619Do not force parts together as all parts are designed for free operation and any binding may cause failure of the drive to fWlctioncTo facilitate reassembly of the starter motor, insert brushes and brush spring in holder, and tie in place with fine wire or stringAssemble brush holder and armature to frame and field assembly, and remove string or wireSee Figure 7-13dReplace commutator and drive end heads to com plete starter motor assemblye Check starter motor with no load testWith 10.0 volts applied to the motor terminals, maximum current should be 60.0 amperes and minimum speed should be 8000 rpm See Figure 7-6