1974 Johnson 135 HP Outboard Motors Service manual, Page 65Get this manual

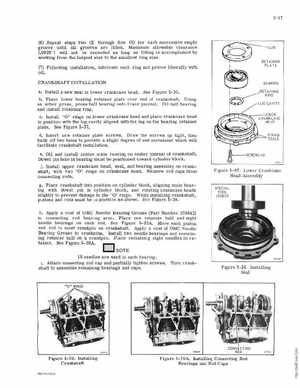

(6) Repeat teps two (2) through five (5) for each successive empt groove until all grooves are filledMaximum allowable clearance (.0025") will not be exceeded as long as fitting is accomplished by working from the la rgest size to the smallest ring size(7) Following installation, lubri cate each ring and groove liberally with oilCRANKSHAFT INSTALLATION aInstall new seal in lower crankcase headSee Figure 5-38bPlace lower bearing retainer plate over end of crankshaft, Using an arbor press, press ball bearing onto lower journalOil ball bearing and install retaining ringcInstall "0" rings on lower crankcase head and place crankcase head in position with the lug cavity aligned with the lug on the bearing et ainer plateSee Figure 5-37 dInsert new etainer plate screwsDraw the screws up tight, then back off two turns to provide light degree of end movement which will facilitate crankshaft installationeOil and install cente main bearing on cente journal of crankshaftDowel pin hole in bearing must be positioned toward cylinde blockInstall upper crankcase head, seal, and bearing assembly on rankshaft, with two "0rings on crankcase headRemove rod caps from connecting rodsgPlace crankshaft into position on cylinder block, aligning maln bear ing with dowel pin in cylinder bloCk, and rotating crankcase heads slightly to prevent damage to the "0" ringsWhile inst alling crankshaft, pistons and rods must be in position as shownSee Figure 5-39hApply coat of OMC Needle Bearing Grease (Part Numbe 378642) to connecting rod bearing area Place one retainer hall and eight needle bearings on each rodSee Figure 5- 39AMove each piston and rod to meet crankpin on crankshaftApply coat of OMC Needle Bearing Grease to rankpinsInstall two needle bearings and remaining retainer half on crankplnPlace remaining eight needles in ret ainerSee Figure 5-39ANOTE 18 needles are used in each bearing1Attach connecting rod cap and partially tighten screwsThrn crankshaft to assemble remaining bear ings and caps;