1974 Johnson 135 HP Outboard Motors Service manual, Page 27Get this manual

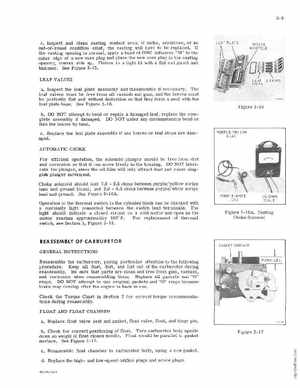

cInspect and clean casting contact areaj if nicks, crat ches, or an out-of-round condition exist, the casting will have to be replacedI the casting opening is normal, apply bead of OMC Adhesive "M" to the outer edge of new core plug and place the new core plug in the casting opening, convex side upFlatten to tight fit with flat end punch and hammerSee Figure 3-15 LEAF VALVES aInspect the leaf plate ssembly and disasse mble if necessaryThe eaf valves must be free from all varni sh and gum, and the leaves must be perfectly flat and without distortion 50 that they form seal with the le af plate baseSee Figure 3- 16bDO NOT attempt to bend repair damaged leaf; replace the complete assembly if damagedDO NOT under any circumstances bend or flex the leaves by handcReplace the eaf plate assembly if any leaves or leaf stops are damagedAUTOMATIC CHOKE or efficient operation, the solenoid plunger hould be fre from dirt and cor rosion 50 that it can move fr eel in the housingDO NOT lubricate the plunger, ince the oil film will only attract dust and cause lugg ish plunge movementChoke solenoid should test 7.08.5 ohms between pur pleyellow tripe lead and gr ound (case), and 3.04.5 ohms between purplewhite stripe lead and groWldSee Figure 3-16AOperation of the the rmal switch in the cylinder block can be checked with continuit light connect ed between the switch lead terminalsThe light should indicate closed cir cuit on cold motor and open as the moto reaches approximatley 100" FFor replacement of thermal switch, see Section 5, Figure 5-13