1973 Evinrude Norseman 40 HP Service Manual, Page 61Get this manual

dApply light coat of OMC Gasket Sealing Compound #317201 to outside diameter of propeller shaft sealPress new seal into oil retainer housingAssemble detent spring and two balls to propeller shaft using OMC Needle Bearing Grease Part Number 378642Align notches in clutch dog with detent balls in propeller shaft, Figure 6-18ANOTE If notches in clutch dog appear off center, ro-

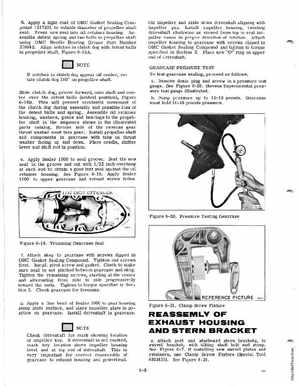

Oil impeller and slide down driveshaft aligning with impeller pinInstall impeller housing, twisting driveshaft clockwise as viewed from top to seal impeller vanes in proper direction of rotationAttach impeller housing to gearcase with screws dipped in OMC Gasket Sealing Compound and tighten to torque specified in Section 2Place new "0" ring on upper end of driveshaftGEARCASE PRESSURE TEST To test gear case sealing, proceed as follows; aRemove drain plug and screw in pressure test gaugeSee Figure 6-20Stevens Experimental pressure test gauge illustratedbPump pressure up to 16-18 poundsGearcase must hold 16-18 pounds pressure

tate clutch dog 180 on propeller shaftSlide clutch dog, groove forward, onto shaft and center over the detent balls (neutral position), Figure 6-18BThis will prevent accidental movement of the clutch dog during assembly and possible loss of the detent balls and springAssemble oil retainer housing, washers, gears and bearings to the propeller shaft in the sequence shown in the illustrated parts catalogBronze side of the reverse gear thrust washer must face gearInstall propeller shaft and components in gearcase with tabs on thrust washer facing up and downPlace cradle, shifter lever and shift rod 'in positioneApply Sealer 1000 to seal grooveSeat the new seal in the groove and cut with 132 inch overhang at each end to obtain good butt seal against the oil retainer housingSee Figure 6-19Apply Sealer 1000 to upper gearcase and around screw holes