1972 Johnson 4HP Outboard Motor Service Manual, Page 48Get this manual

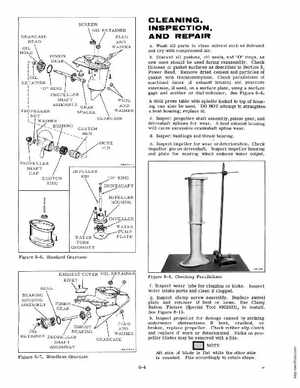

GEARCASE HEAD

CLEANING, INSPECTION, AND REPAIR

PROPJi:LLERSHAFT PLUG ASSEMBLY GEAR AND PROPELLER SPACER WASHERNUT ASHER GEARCASE

Wash parts in clean solvent such as Solvasol and dry with compressed airDiscard gaskets, oil seals, and rings, as new ones should used during reassemblyCheck flatness of gasket surfaces as described in Section 5, Power HeadRemove dried cement and particles of gasket with trichlorethyleneCheck parallelism machined faces exhaust housing and gearcase extension, if used, surface plate, using surface gage and scriber or dial indicatorSee Figure 6-8drill press table with spindle locked to top of housing also usedDO NOT attempt to straighten bent housing; replace itInspect propeHer shaft assembly, pinion gear, and driveshaft splines for wearbent exhaust housing wiH cause excessive crankshaft spline weardInspect bushings and thrust bearingInspect impeHer for wear or deteriorationCheck impeHer pin driveshaftInspect impeHer housing and plate for scoring which reduces water output