1971 Johnson 4HP Outboard Motors Service Manual, Page 40Get this manual

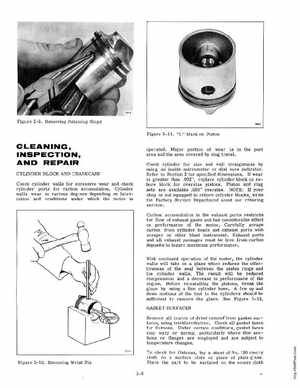

Figure 5-9Removing Retaining Rings Figure 5-11"L" Mark Piston

CLEANING, INSPECTION, AND REPAIR

CYLINDER BLOCK AND Check cylinder wal1s for excessive wear and check cylinder ports for carbon accumu1ationCylinder waHs wear in various degrees depending 1ubrication and conditions under which the motor is

operatedMajor portion of wear is in the port area and the area covered ring trave1Check cylinder for size and wal1 straightness using an inside micrometer or dia1 bore indicatorRefer to Section for specified dimensionsIf wear is greater than .002", rep1ace cylinder block or rebore block for oversize pistonsPiston and ring sets are available .030" oversizeNOTE: If your shop is not equipped to rebore cylinder blocks, write the Factory Service Department about our reboring serviceCarbon accumu1ation in the exhaust ports restricts the flow of exhaust gases and has considerable effect performance of the motorCarefuHy scrape carbon from cylinder heads and exhaust ports with scraper or other blunt instrumentExhaust ports and exhaust passages must free from carbon deposits to insure maximum performanceWith continued operation of the motor, the cylinder waHs will take pn g1aze which reduces the effectiveness of the seal between the piston rings and the cylinder waHsThe resu1t wi1l reduced compression and decrease in performance of the engineBefore reinstalling the pistons, break the g1aze using fine cylinder honefew and down motions of the to01 in the cylinders shou1d sufficient to remove the g1azeSee Figure 5-12GASKET SURFACES Remove traces of dried cementfrom gasket surfaces, using trichlorethy1eneCheck gasket faces for flatnessUnder certain conditions, gasket faces warp or spring, particu1ar1y where thin tions or flanges are emp10yed and are subject to temperature changesZ014