1971 Johnson 4HP Outboard Motors Service Manual, Page 20Get this manual

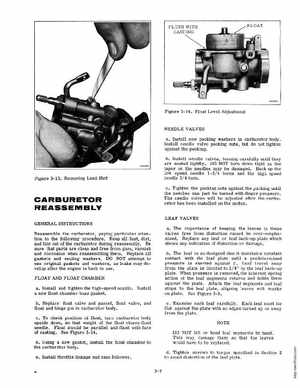

Figure 3-14Float Level Adjustment

NEEDLE VAL VES Install new packing washers in carburetor bodyInstall needle valve packing nuts, but do not tighten against the packingInstall needle valves, turning carefully until they seated lightlyDO turn down tight as the taper the needles damagedBack the low speed needle 1-3 turns and the high speed needle 3 turnTighten the packing nuts against the packing until the needles can just turned with finger pressureneedle valves will adjusted after the retor has been installed the motorLEAF VALVES GENERAL INSTRUCTIONS Reassemble the carburetor, paying particular attention to the following proceduredust, dirt, and lint out of the carburetor during reassemblysure that parts are clean and free from gum, varnish and corrosion when reassembling themReplace gaskets and sealing washersDO NOT attempt to use original gaskets and washers, as leaks develop after the engine is back in useFLOAT AND FLOAT Install and tighten the high-speed nozzleInstall new float boss gasketReplace- float valve and gasket, float valve, and float and hinge pin in carburetor bodycheck position of float, turn carburetor body upside down, so that weight of the float closes float needleFloat should parallel and flush with face castingSee Figure 3-14dUsing new gasket, install the float the carburetor bodyInstall throttle linkage and follower 3- 7