1971 Johnson 2HP outboards Service Manual, Page 36Get this manual

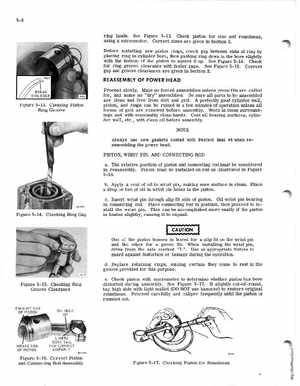

5-6 ring landsSee Figure 5-13Check piston for size and rOWldness, using micrometerCorrect sizes are given in Section 2Before installing new piston rings, check gap between ends of ring by placing ring in cylinder bore, then pushing ring down in the bore slightly with the bottom of the piston to square it upSee Figure 5-14Check for ring groove clearance with feeler gageSee Figure 5-15Correct gap and groove clearances are given in Section 2 REASSEMBLY OF POWER HEAD

Proceed slowlyMake no forced assemblies unless press fits are called forand make no "dry" assembliesBe sure all parts to be assembled are clean and free from dirt and gritA perfectly good cylinder wail, piston, and rings can be ruined in few minutes of operation unless all forms of grit are removed before assemblyWork in clean surroWldings and with reasonably clean handsCoat all bearing surfaces, cylinder wall, etc, with clean oil before assemblyNOTE Always use new gaskets coated with Perfect Seal #4 when reassembling the power headPISTON, WRIST PIN, AND CONNECTING ROD aThe relative poSition of piston and connecting rod must be considered in reassemblyPiston must be installed on rod as illustrated in Figure 5-16bApply coat of oil to wrist pin, making sure surface is cleanPlace drop or two of oil in wrist pin holes in the pistoncInsert wrist pin through slip fit side of pistonOil wrist pin bearing in connecting rodPlace connecting rod in position, then proceed to install the wrist pinThis can be accomplished more easily if the piston is heated slightly, causing it to expand