1971 Evinrude 40HP outboards Service Manual, Page 45Get this manual

DO NOT scratch cylinder head gasket surface of cylinderUse surface plate to surface this areaWith continued operation of the motor, the cylinder walls will take on glaze which reduces the effectiveness of the seal between the piston rings and the cylinder wallsThe result will be reduced compression and decrease in performance of the engine Before reinstalling the pistons, break the glaze by using fine cylinder hone to refinish cylinder wallsA few up and down motions of the tool should be sufficient to remove cylinder wall glazeSee Figure 5-15Blowout all oil passages and drainsGASKET SURFACES Remove all traces of dried cement, USing trichlorethylene or lacquer thinner Check all gasket faces for flatnessUnder certain conditions, gasket faces may warp or spring, particularly where thin sections

REFERENCE PICTURE

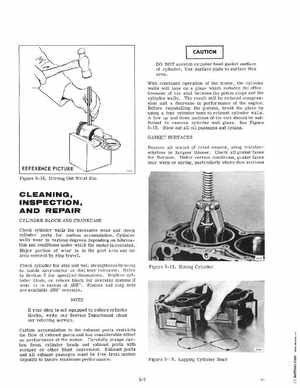

Figure 5-14Driving Out Wrist Pin

CLEANING, INSPECTION, AND REPAIR

CYLINDER BLOCK AND CRANKCASE Check cylinder walls for excessive wear and check cylinder ports for carbon accumulationCylinder walls wear in various degrees depending on lubrication and conditions under which the motor is operatedMajor portion of wear is in the port area and the area covered by ring travelCheck cylinder for size and wall straightness by using an inside micrometer or dial bore indicatorRefer to Section for specified dimensionsReplace cylinder block, or rebore block for oversize pistons if wear is in excess of .003"Pistons and ring sets are available .030" oversizeNOTE