1970 Johnson 1.5 HP Outboard Motor Service Manual, Page 38Get this manual

5-8 dMove piston so that connecting rod bearings are against crankpinUsing Needle Bearing Grease, place 16 needles crankpin and attach connecting rod See Figure 5- 23sure the connecting rod dowel pins are in place before atlaching connecting rod and the lock plates are the connecting rod screwsTighten screws to torque specified in Section 2Install lower bearing housing with new gasket and tighten screws to torque spe,c ified in Section 2fCheck whether the needles are in place in the assembled connecting rod bearing inserting small rod wire through the oil hole in the It will not possible to touch the crankpin with the wire if the correct number of needles has been usedSee Figure 5-24gCheck for binding of the connecting rodRod should float freely over the full length of the crankpinIf rod binds, check alignmentSee Figure 5-24Bend lock plates to prevent connecting rod loosening and backing outscrews from

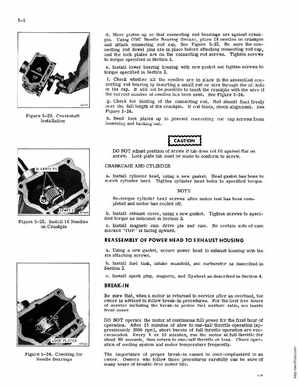

Figure 5-22Crankshaft Installation

DO NOT adjust position of screw if tab does not fit against flat screwLock plate tab must to conform to screwAND CYLINDER Install cylinder head, using new gasketHead gasket has boss to match cylinder Tighten cylinder head bolts to specified torqueNOTE Re-torque cylinder head screws after motor test has been pleted and motor has cooled offInstall exhaust cover, using new gasketfied torque as indicated in Section 2Install magneto drive pin and marked is facing upwardTighten screws to specicertain side of