1969 Evinrude 40 HP Big Twin, Big Twin Electric Lark Service Manual 4596, Page 89Get this manual

PLUNGER

WINDINGS

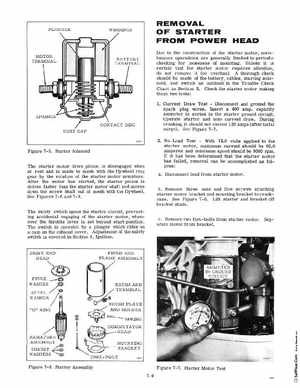

REMOVAL OF STARTER FROM POWER HEAD

Due to the construction of the starter motor, maintenance operations are generally limited to periodic checking for looseness of mountingUnless it is certain that the starter motor requires attention, do not remove it for overhaulA thorough check should be made of the battery, cables, starting solenOid, and switch as outlined in the Trouble Check Chart in Section 2Check the starter motor making these two tests :

1Current Draw TestDisconnect and ground the

spark plug wiresInsert 400 ampcapacity ammeter in series in the starter ground circuitOperate starter and note current drawDuring cranking it should not exceed 120 amps (after inital surge)See Figure 7-73404

DUST CAP

Figure 7-5Starter Solenoid The starter motor drive pinion is disengaged when at rest and is made to mesh with the flywheel ring gear by the rotation of the starter motor armatureAfter the motor has started, the starter pinion is driven faster than the starter motor shaft and moves down the screw shaft out of mesh with the flywheelSee Figures 7-6 and 7-9The safety switch opens the starter circuit, preventing accidental engaging of the starter motorwhenever the throttle lever is set beyond start positionThe switch is operated by plunger which rides on cam on the exhaust coverAdjustment of the safety switch is covered in Section 4, IgnitionFIELD AND FRAME ASSEMBLY