1969 Evinrude 40 HP Big Twin, Big Twin Electric Lark Service Manual 4596, Page 39Get this manual

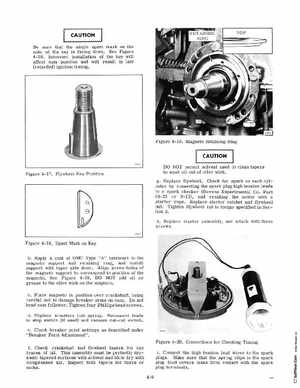

Be sure that the single upset mark on the side of the key is facing downSee Figure 4-18Incorrect installation of the key will affect cam position and will result in late (retarded) ignition timing Figure 4-19Magneto Retaining Ring

Figure 4-17Flywheel Key Position

DO NOT permit solvent used to clean tapers to wash oil out of oiler wickgReplace flywheelCheck for spark on each cylinder by connecting the spark plug high tension leads to spark checker (Stevens Experimental CoPart #S-21 or S-13), and cranking the motor with starter ropeReplace starter ratchet and flywheel nutTighten flywheel nut to torque specified in Section 2hReplace starter assembly, and attach with three screws

Figure 4-18Upset Mark on Key bApply coat of OMC Type "A" lubricant to the magneto support and retaining ring, and install support with taper side downAlign screw holes of the magneto support to correspond to position of the magnetoSee Figure 4-19DO NOT add oil or grease to the oiler wick on the magnetocPlace magneto in position over crankshaft, being careful not to damage breaker arms on camDo not bend cam followerTighten four Phillips head screwsd Replace armature link springReconnect leads to stop switch (if used) and vacuum cut-out switcheCheck breaker point settings as described under "Breaker Point Adjustment"Figure 4-20Connections for Checking Timing fCheck crankshaft and flywheel tapers for any traces of oilThis assembly must be perfectly dryswab tapered surfaces with solvent and blow dry with compressed airInspect both tapers for burrs or nicks4-9