1968 Evinrude Speedifour, Starflite 85HP Service Manual, Page 23Get this manual

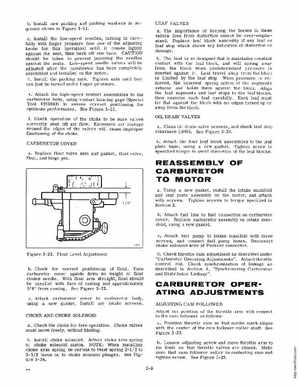

Insta1l new packing and packing washers in sequence shown in Figure 3-11Insta1l the low-speed needles, turning in fu1ly with finger pressure (use of the adjusting knobs for this operation) it comes lightly against the seat, then back off one turnCAUTION should taken to prevent jamming the needles against the seatsLow-speed needle valves will adjusted after the carubretor has been completely assembled and installed the motordInstal1 the packing nutsTighten nuts until they just turned under finger pressureAttach the high-speed venturi assemblies to the carburetor body, using venturi locating gage (Special Tool #379242) to assure correct positioning for optimum performanceSee Figure 3-21fCheck of the choke to sure valves correctly shut off air flowExcessive air leakage around the edges of the valves wi1l cause improper functioning of the chokeCARBURETOR COVER Replace float valve seat and gasket, float valve, float, and hinge pin LEAF VALVES The importance of keeping the leaves in these valves free from distortion cannot over-emphasizedReplace leaf block assembly if any leaf leaf stop which shows indication of distortion damageThe leaf is so designed that it maintains constant contact with the leaf block, and will spring away from the block when predetermined pressure is exerted against itLeaf travel away from the block is limited the leaf stopWhen pressure is moved, the inherent spring action of the segments returns and ho1ds them against the block Align the leaf segments and leaf stops to the leaf blocks, then examine each leaf careful1yEach leaf must lie flat against the block with edges turned away from the blockOIL DRAIN VAL VES Clean oil drain valve screens, and check leaf stop clearance (.040)See Figure 3-28Attach the four leaf block assemblies to the leaf plate base, using new gasketTighten sc rew to specified torque to avoid distortion of the leaf blocks