1968 Evinrude Speedifour, Starflite 85HP Service Manual, Page 20Get this manual

CLEANING, INSPECTION, AND REPAIR GENERAL INSTRUCTIONS parts, except float and inlet needle, in solvent and blow dryDO NOT dry parts with cloth as lint cause trouble in the reassembled carburetorsure particles of gaskets removed from gasket surfacesFlush out passages in the buretor body with solvent and remove gummy deposits with Accessory Engine Cleanertain solvents will not remove this gum which cumulates particularly in the float chamber and the needle valvesFLOAT AND NEEDLE VALVES

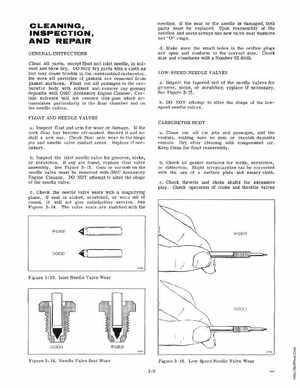

needles; if the seat the needle is damaged, both parts must replacedUpon reassembly of the needles and seats always use new valve seat washers and ringsdMake sure the smaH holes in the orifice plugs open and conform to the correct sizeCheck size and roundness with Number 52 drillLOW-SPEED NEEDLE VALVES Inspect the tapered end of the needle valves for grooves, nicks, scratches; replace if necessarySee Figure 3-15DO NOT attempt to alter the shape of the lowspeed needle valvesCARBURETOR BODY

Inspect float and for wear damageIf the cork float has oil-soaked, discard it and install new oneCheck float wear in the hinge pin and needle valve contact areasReplace if necessaryInspect the inlet needle valve for grooves, nicks, scratchesIf any foundreplace float valve assemblySee Figure 3-13Gum varnish the needle valve must removed with Accessory Engine CleanerDO NOT attempt to alter the shape of the needle valveCheck the needle valve seats with magnifying glassIf seat is nicked, scratched, worn out of round, it will not give satisfactory serviceSee Figure 3-14The valve seats matched with the