1968 Evinrude Big Twin, Big Twin Electric, Lark 40 HP Outboards Service Manual, Page 53Get this manual

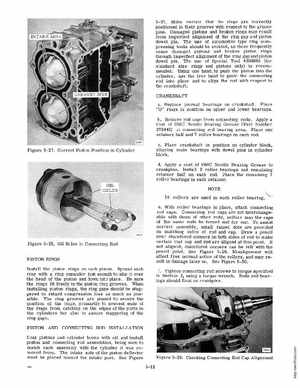

5-27Make certain that the rings are correctly positioned in their grooves with respect to the groove pinsDamaged pistons and broken rings result from imperfect alignment of the ring gap and piston dowel pinThe use of automotive type ring pressing tools should avoided, as these frequently cause damaged pistons and broken piston rings through imperfect alignment of the ring gap and piston dowel pinThe use of Special #308866 (for standard size rings and pistons only) is recommendedUsing one handto push the piston into the cylinder, use the free hand to guide the connecting rod into place and to align the rod with respect to the crankshaft Replace journal bearings crankshaftPlace rings in position upper and lower bearingsRemove rod caps from connecting rodsApply coat of Needle Bearing Grease (Part Number 378642) to connecting rod bearing areaPlace one retainer half and roller bearings each rodFigure 5-27Correct Piston Position in Cylinder Place crankshaft in position cylinder block, aligning main bearings with dowel pins in cylinder blockdApply coat of Needle Bearing Grease to crankpinsInstall roller bearings and remaining retainer half each rodPlace the remafuing roller bearings in each retainerNOTE 16 rollers are used in each roller bearing'-With roller bearings in place, attach connecting rod capsConnecting rod caps are not interchangewith those of other rods, neither the caps of the same rods turned end for endassist correct assembly, small raised dots are provided matching sides of rod and Draw pencil over chamfered corners both sides of rod to make certain that and rod are aligned at this pointIf not aligned, chamfered corners felt with the pencil pointSee Figure 5- 29Misalignment will affect free normal action of the rollers, and result in damage later See Figure 5-30fTighten connecting rod screws to torque specified in Section 2, using torque wrenchRods and bearings should float crankpins