Honda BF15D BF20D Outboard Motors Shop Manual., Page 177Get this manual

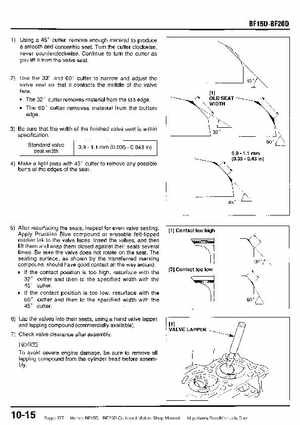

1) Usingcutter, remove enough material to produce smooth and concentric seatTurn the cutter clockwise, never counterclockwiseContinue to turn the cutter as you lift it from the valve seat2) Use the 32' and 60' cutter to narrow and adjust the valve seat so that it contacts the middle of the valve faceThecutter removes material from the top edge2 The 60' cutter removes material from the bottom edge 3) Be sure that the width of the finished valve seat is within specification

Standard valve seat width

0.91.1 rnm (0.0350.043 in)

4) Make light pass with 45' cutter to remove any possible

burrs at the edges of the seat

After resurfacing the seats, inspect for even valve seatingApply Prussian Blue compound or erasable felt-tipped marker ink to the valve facesInsert the valves, and then lift them and snap them closed against their seats several timesBe sure the valve does not rotate on the seatThe seating surface, as shown by the transferred marking compound, should have good contact all the way arounda If the contact position is too high, resurface with the 32' cutter and then to the specified width with the cutterIf the contact position is too low, resurface with the 60' cutter and then to the specified width with the cutter6) Lap the valves into their seats, using hand valve lapper and lapping compound (commercially available)7) Check valve clearance after assembly