Chrysler 75 and 85 HP Outboards Service Manual OB 3646, Page 180Get this manual

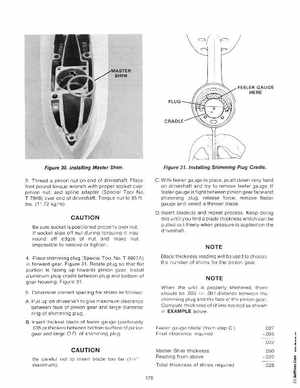

FEELER GAUGE HERE PLUG

Figure 30Installing Master Shim3Thread pinion nut on end of driveshaftPlace foot pound torque wrench with proper socket over pinion nutand spline adapter (Special Tool No 7848) over end of driveshaftTorque nut to 85 ftIbs(11.72 kgm)

Figure 31Installing Shimming Plug CradleC With feeler gauge in placepush down very hard on driveshaft and try to remove feeler gaugeIf feeler gauge is tight between pinion gear face and shimming plugrelease forceremove feeler gauge and select thinner bladeD.lnsert blade(s) and repeat processKeep dOing this until you find blade thickness which can be pulled out freely when pressure is applied on the driveshaft

CAUTION

Be sure socket is positioned properly over nutIf socket sl ips off nut during torquing it may round off edges of nut and make nut impossible to remove or tighten 4Place shimming plug (Special Tool No 8997 A) in forward gearFigure 31Rotate plug so that flat portion is facing up towards pinion gearInstall aluminum plug cradle between plug and bottom of gear housing Figure 315Determine correct spacing for shims as follows :