Chrysler 70, 75 and 85 HP Outboard Motors Service Manual OB 3438, Page 198Get this manual

2Dry parts with compressed air3Inspect propeller shaft for wear or distortion around clutch slot and propeller pin hole Remove sharp burrs or nicks with fine file or emery cloth Check spline for cracks4Inspect clutch for wearReplace if wornPay particular attention to clutch dogs5Check coupling, shift pin and yoke for wear 6Check propeller shaft bearing cage bearing for wear7Check gears for wearTeeth should look evenly "polished 8Inspect rear gear bearings as follows :

ACheck I.Dof bronze bearing for galling

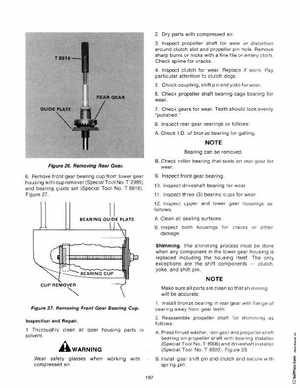

Bearing can be removedFigure 26Removing Rear Gear

BCheck roller bearing that seats on rear gear for wear9Inspect front gear bearing 10Inspect driveshaft bearing for wear11 Inspect three (3) bearing cups for wear12Inspect upper and lower gear housings as follows :

6Remove front gear bearing cup from lower gear housing with cup remover (Special Tool NoT 2995) and bearing guide set (Special Tool NoT 8918)Figure 27

BEARING GUIDE PLATE

AClean all sealing surfaces BInspect both housings for cracks or other damage ShimmingThe shimming process must be done when any component in the lower gear housing is replaced including the housing itselfThe only exceptions are the shift componentsclutchyoke, and shift pin