Chrysler 6, 7.5, 180 Sailor Outboard Motors Service Manual, OB 3330, Page 99Get this manual

3Install assembled piston into cylinder bore as follows:

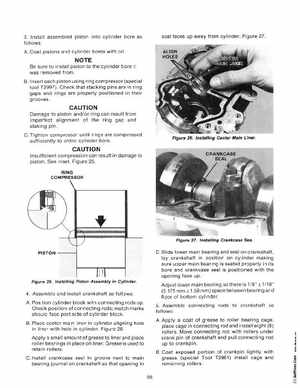

seal faces up away from cylinderFigure 27

ACoat pistons and cylinder bores with oil

Be sure to install piston to the cylinder bore it was removed from BInsert each piston using ring compressor (special tool T2997) Check that stacking pins are in ring gaps and rings are properly positioned in their grooves

CAUTION

Damage to piston andor ring can result from imperfect alignment of the ring gap and staking pinCTighten compressor until rings are compressed sufficiently to entire cylinder boreFigure 26Installing Center Main Liner

CAUTION

Insufficient compression can result in damage to piston See insetFigure 25 RING COMPRESSOR

Figure 27Installing Crankcase SeaPISTON ""'""'"!

DSlide lower main bearing and seal on crankshaftlay crankshaft in position on cylinder making sure upper main bearing is seated properly in its bore and crankcase seal is pOSitioned with the opening face upAdjust lower main bearing so there is 1 8" 1 16" (3 .175 mm 1.59 mm) space between bearing and floor of bottom cylinder5Assemble connecting rods to crankshaft as follows: