Chrysler 6, 7.5, 180 Sailor Outboard Motors Service Manual, OB 3330, Page 97Get this manual

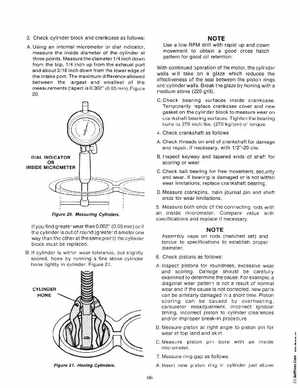

3Check cylinder block and crankcase as follows: AUsing an internal micrometer or dial indicator, measure the inside diameter of the cylinder at three points Measure the diameter 14 inch down from the top, 14 inch up from the exhaust port and about 316 inch down from the lower edge of the intake portThe maximum difference allowed between the largest and smallest of the measurements (taper) is 0.002" (0 .05 mm) Figure 20 NOTE

Use low RPM drill with rapid up and down movement to obtain good cross hatch pattern for good oil retentionWith continued operation of the motor, the cylinde walls will take on glaze which reduces the effectiveness of the seal between the piston rings and cylinder wallsBreak the glaze by honing with medium stone (220 grit)CCheck bearing surfaces inside crankcaseTemporarily replace crankcase cover and new gasket on the cylinder block to measure wear on crankshaft bearing surfacesTighten the bearing bolts to 270 inch Ibs(270 kg cm) of torque4Check crankshaft as follows:

ACheck threads on end of crankshaft for damage