Chrysler 4 HP Outboard Motor Service Manual OB 2278, Page 51Get this manual

SECTION XI (Con't 6-2Installing Connecting Rod Needle Bearings

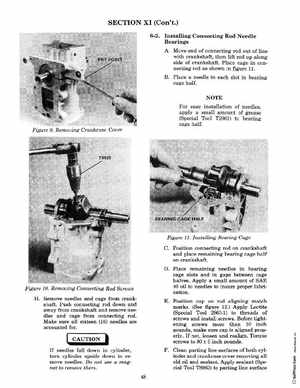

AMove end of connecting rod out of line with crankshaft, then lift rod up along side of crankshaftPlace cage in connecting rod as shown in figure 11BPlace needle in each slot in bearing cage half

For easy installation of needles, apply small amount of grease (Special Tool T2961) to bearing cage half

Figure 9Removing Crankcase Cover

Figure 11Installing Bearing Cage

CPosition connecting rod on crankshaft and place remaining bearing cage half on crankshaftDPlace remaining needles in bearing cage slots and in gaps between cage halvesApply small amount of SAE 40 oil to needles to insure proper lubricationEPosition cap on rod aligning match marks(See figure 12 Apply Loctite (Special Tool 2963-1) to threads of screws and install screwsBefore tightening screws more than 10 inch pounds, make sure cap is aligned properlyIf not, loosen and realignTorque screws to 80 inch poundsFClean parting line surfaces of both cylinder and crankcase cover removing all old oil and sealantApply sealant (Special Tool T8983) to parting line surface 48