Chrysler 20 and 30 HP Outboard Motors Service Manual OB 3435, Page 110Get this manual

NOTE Inspect insulated brush ohmmeter for shorts assembly with

CAUTION

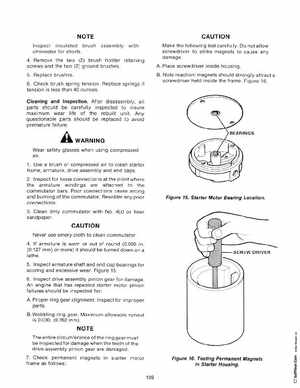

Make the following test carefullyDo not allow screwdriver to strike magnets to cause any damage

4Remove the two (2) brush holder retaining screws and the two (2) ground brushes5Replace brushes6Check brush spring tension Replace springs if tension is less than 40 ounces

APlace screwdriver inside housing BNote reactionmagnets should strongly attract screwdriver held inside the frame Figure 16

Cleaning and InspectionAfter disassembly, all parts should be carefully inspected to insure maximum wear life of the rebuilt unitAny questionable parts should be replaced to avoid premature failure

WARNING

Wear safety glasses when using compressed air1Use brush or compressed air to clean starter frame, armature, drive assembly and end caps 2Inspect for loose connections at the point where the armature windings are attached to the commutator barsPoor connections cause arcing and burning of the commutatorResolder any poor connections 3Clean dirty commutator with No 400 or finer sandpaper