Chrysler 100, 115 and 140 HP Outboard Motors Service Manual, OB 3439, Page 137Get this manual

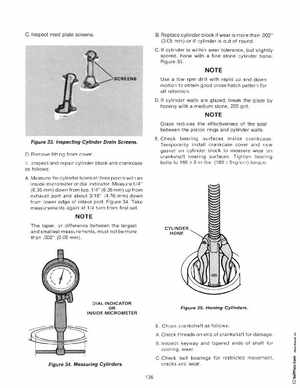

Clnspect reed plate screens BReplace cylinder block if wear is more than .002" (0 .05 mm) or if cylinder is out of round C.lf cylinder is within wear tolerancebut slightly scoredhone with fine stone cylinder honeFigure 35

SCREENS

Use low rpm drill with rapid up and down motion to obtain good cross hatch pattern for oil retention Dlf cylinder walls are glazedbreak the glaze by honing with medium stone220 grit

Glaze reduces the effectiveness of the seal between the piston rings and cylinder walls Figure 33Inspecting Cylinder Drain Screens

DRemove fitting from cover7Inspect and repair cylinder block and crankcase as follows :

AMeasure the cylinder bores at three points with an

ECheck bearing surfaces inside crankcaseTemporarily install crankcase cover and new gasket on cylinder block to measure wear on crankshaft bearing surfacesTighten bearing bolts to 160 in Ibs(183 5kg cm) torqu e