2009 Polaris Scrambler 500 4x4 2x4 factory service manual, Page 73Get this manual

VALVE SEAT SERVICE

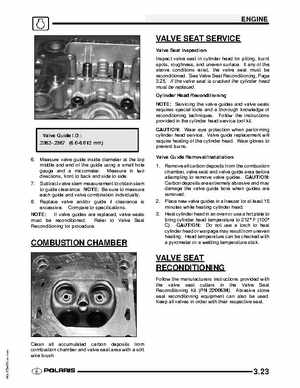

Valve Seat Inspection Inspect valve seat in cylinder head for pitting, burnt spots, roughness, and uneven surfaceIf any of the above conditions exist, the valve seat must be reconditionedSee Valve Seat Reconditioning, Page 3.25If the valve seat is cracked the cylinder head must be replacedCylinder Head Reconditioning NOTE: Servicing the valve guides and valve seats requires special tools and thorough knowledge of reconditioning techniquesFollow the instructions provided in the cylinder head service tool kitValve Guide I.D .2362-.2367 (6.0-6.012 mm) 6Measure valve guide inside diameter at the top middle and end of the guide using small hole gauge and micrometerMeasure in two directions, front to back and side to side7Subtract valve stem measurement to obtain stem to guide clearanceNOTE: Be sure to measure each guide and valve combination individually8Replace valve andor guide if clearance is excessiveCompare to specificationsNOTE: If valve guides are replaced, valve seats must be reconditionedRefer to Valve Seat Reconditioning for procedureCAUTION: Wear eye protection when performing cylinder head serviceValve guide replacement will require heating of the cylinder headWear gloves to prevent burnsValve Guide RemovalInstallation 1Remove all carbon deposits from the combustion chamber, valve seat and valve guide area before attempting to remove valve guidesCAUTION: Carbon deposits are extremely abrasive and may damage the valve guide bore when guides are removed2Place new valve guides in freezer for at least 15 minutes while heating cylinder head3Heat cylinder head in an oven or use hot plate to bring cylinder head temperature to 212 (100 C)CAUTION: Do not use torch to heat cylinder head or warpage may result from uneven heatingHead temperature can be checked with pyrometer or welding temperature stick